Table of Contents

Benefits of Customized Electric Grab Cranes for Industrial Applications

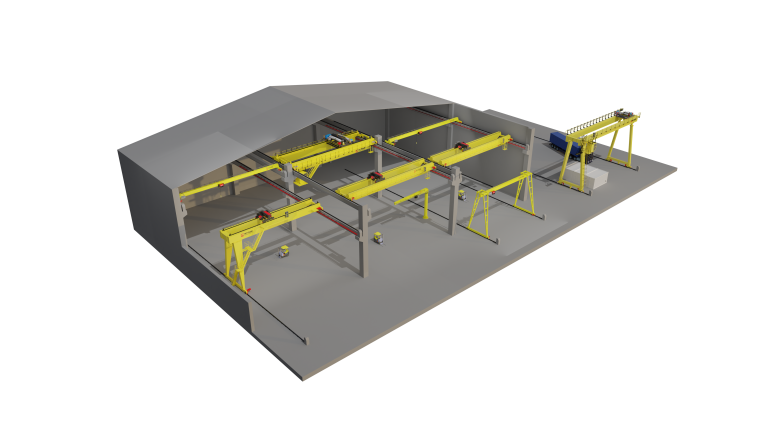

Electric grab cranes have become an essential tool in various industrial applications, providing efficient and reliable material handling solutions. These cranes are designed to lift and transport heavy loads with precision and ease, making them a valuable asset for industries such as construction, mining, and manufacturing. While standard electric grab cranes are readily available in the market, many companies are now opting for customized solutions to meet their specific requirements.

One of the key benefits of opting for a customized electric grab crane is the ability to tailor the crane to suit the unique needs of the application. By working closely with a reputable crane manufacturer, companies can specify the size, capacity, and features of the crane to ensure optimal performance and efficiency. This level of customization allows companies to maximize productivity and minimize downtime, ultimately leading to cost savings in the long run.

Customized electric grab cranes are also designed to meet the safety standards and regulations of the industry. By incorporating safety features such as overload protection, emergency stop buttons, and anti-collision systems, companies can ensure the well-being of their workers and prevent accidents in the workplace. Additionally, customized cranes can be equipped with advanced technology such as remote monitoring and diagnostics, allowing for real-time tracking of the crane’s performance and maintenance needs.

Another advantage of opting for a customized electric grab crane is the flexibility it offers in terms of operation. Companies can choose from a range of control options, including radio remote control, pendant control, or cabin control, depending on their specific requirements. This level of customization allows operators to work more efficiently and comfortably, ultimately improving overall productivity and job satisfaction.

Furthermore, customized electric grab cranes are designed to be durable and reliable, ensuring long-term performance and minimal maintenance requirements. By using high-quality materials and components, companies can expect their crane to withstand the rigors of daily use and operate smoothly for years to come. This level of reliability is crucial for industries that rely on continuous material handling operations to meet production targets and deadlines.

In conclusion, customized electric grab cranes offer a range of benefits for industrial applications, including tailored design, enhanced safety features, operational flexibility, and long-term reliability. By investing in a customized crane, companies can improve efficiency, productivity, and safety in the workplace, ultimately leading to a more profitable and sustainable operation. With the help of a reputable crane manufacturer, companies can design a crane that meets their specific needs and exceeds their expectations, making it a valuable asset for their business.

How to Choose the Right Electric Grab Crane for Your Company’s Needs

Electric grab cranes are an essential piece of equipment for many industries, including construction, mining, and shipping. These powerful machines are used to lift and move heavy materials with ease, making them a valuable asset for any company that deals with large loads on a regular basis. If you are in the market for a new electric grab crane for your business, it is important to choose the right one to meet your specific needs. In this article, we will discuss how to select the perfect electric grab crane for your company.

When it comes to choosing an electric grab crane, one of the most important factors to consider is the capacity of the crane. The capacity of a crane refers to the maximum weight that it can lift safely. It is crucial to select a crane with a capacity that is suitable for the types of materials that you will be moving. If you choose a crane with a capacity that is too low, you may not be able to lift all of the materials that you need to. On the other hand, if you choose a crane with a capacity that is too high, you may be wasting money on a crane that is more powerful than you need.

Another important factor to consider when choosing an electric grab crane is the reach of the crane. The reach of a crane refers to the distance that the crane can extend its arm to pick up and move materials. It is important to select a crane with a reach that is appropriate for the size of your work area. If you choose a crane with a reach that is too short, you may not be able to reach all of the materials that you need to move. Conversely, if you choose a crane with a reach that is too long, you may have difficulty maneuvering the crane in tight spaces.

In addition to capacity and reach, it is also important to consider the power source of the electric grab crane. Electric grab cranes can be powered by either electricity or diesel fuel. Electric cranes are typically more environmentally friendly and cost-effective to operate, but they may not be suitable for all applications. Diesel-powered cranes are more powerful and can be used in remote locations where electricity is not readily available. When choosing a power source for your electric grab crane, consider the specific needs of your company and the environment in which the crane will be operating.

Once you have determined the capacity, reach, and power source of the electric grab crane that you need, it is time to consider customization options. Many companies that manufacture electric grab cranes offer customization services to meet the unique needs of their customers. Customization options may include additional safety features, specialized attachments, or modifications to the crane’s design. When selecting a company to purchase your electric grab crane from, be sure to inquire about their customization options and choose a company that is willing to work with you to create a crane that meets your specific requirements.

In conclusion, choosing the right electric grab crane for your company’s needs is a crucial decision that can have a significant impact on your business operations. By considering factors such as capacity, reach, power source, and customization options, you can select a crane that is perfectly suited to your company’s requirements. Take the time to research different crane manufacturers and compare their products to find the best electric grab crane for your business. With the right crane in place, you can improve efficiency, increase productivity, and ensure the safety of your employees.

Case Studies: Successful Implementations of Customized Electric Grab Cranes in Various Industries

Electric grab cranes have become an essential tool in various industries, allowing for efficient and safe material handling. These cranes are versatile and can be customized to meet the specific needs of different industries. One company that specializes in providing customized electric grab cranes is Company X. They have successfully implemented customized electric grab cranes in various industries, helping their clients improve their operations and increase productivity.

| No. | Product |

| 1 | QD OVERHEAD CRANE WITH HOOK CAP.5-800/150T |

| 2 | Rubber – tired Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

One of the industries that Company X has worked with is the construction industry. Construction sites often require heavy lifting and material handling, which can be challenging without the right equipment. Company X worked closely with a construction company to design and install an electric grab crane that could handle the specific needs of their construction site. The crane was customized to lift heavy materials such as steel beams and concrete blocks, making the construction process more efficient and safe.

Another industry that Company X has successfully implemented customized electric grab cranes is the shipping and logistics industry. Shipping ports and warehouses require efficient material handling to ensure timely delivery of goods. Company X worked with a shipping company to design and install an electric grab crane that could handle the loading and unloading of containers. The crane was customized to have a higher lifting capacity and faster operation, allowing the shipping company to increase their throughput and reduce downtime.

In the mining industry, Company X has also made significant contributions by providing customized electric grab cranes. Mines require heavy-duty equipment to handle the extraction and transportation of minerals. Company X worked with a mining company to design and install an electric grab crane that could handle the harsh conditions of a mine site. The crane was customized with special coatings and materials to withstand the abrasive nature of mining operations, ensuring reliable performance and minimal maintenance.

Company X’s success in implementing customized electric grab cranes in various industries can be attributed to their expertise and commitment to meeting their clients’ specific needs. They work closely with each client to understand their requirements and design a crane that is tailored to their operations. By customizing the cranes, Company X ensures that their clients can maximize efficiency, improve safety, and reduce operational costs.

In conclusion, electric grab cranes have become an indispensable tool in various industries, allowing for efficient and safe material handling. Company X has demonstrated their expertise in providing customized electric grab cranes to meet the specific needs of different industries. By working closely with their clients and designing cranes that are tailored to their operations, Company X has helped improve productivity and streamline operations in the construction, shipping, logistics, and mining industries. Their successful implementations serve as a testament to the importance of customization in maximizing the benefits of electric grab cranes in various industries.