Table of Contents

Top 10 Must-Have Crane Parts for Efficient Operations

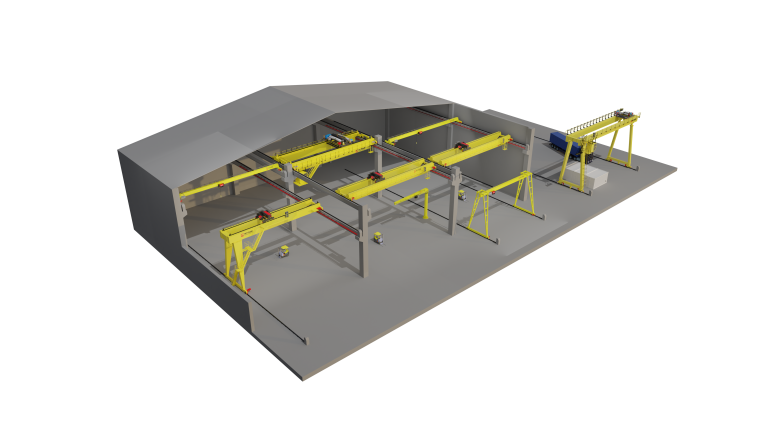

Cranes are essential equipment in various industries, from construction to manufacturing. They are used to lift and move heavy loads with precision and efficiency. To ensure that cranes operate smoothly and safely, it is important to have the right crane parts on hand. In this article, we will discuss the top 10 must-have crane parts for efficient operations.

1. Wire ropes: Wire ropes are used to lift and lower loads in cranes. They are made of high-strength steel wires twisted together to provide strength and flexibility. It is important to regularly inspect wire ropes for wear and tear and replace them when necessary to prevent accidents.

2. Hooks: Hooks are attached to the end of the wire ropes to lift and secure loads. They come in various sizes and designs to accommodate different load capacities. It is important to choose the right hook for the job to ensure safe lifting operations.

3. Sheaves: Sheaves are pulleys with grooved wheels that guide wire ropes and cables in cranes. They help to reduce friction and wear on the ropes, allowing for smoother and more efficient lifting operations. It is important to regularly inspect sheaves for wear and tear and replace them when necessary.

4. Bearings: Bearings are used to support and guide moving parts in cranes, such as the boom and trolley. They help to reduce friction and wear on the moving parts, allowing for smoother and more efficient crane operations. It is important to regularly lubricate and inspect bearings to ensure they are in good working condition.

5. Brakes: Brakes are essential safety devices in cranes that help to control the speed and movement of the load. They are used to stop and hold the load in place during lifting operations. It is important to regularly inspect and maintain brakes to ensure they are functioning properly.

6. Motors: Motors are used to power the movement of cranes, such as lifting and lowering the load. They come in various sizes and power ratings to accommodate different crane models and load capacities. It is important to regularly inspect and maintain motors to ensure they are in good working condition.

7. Control systems: Control systems are used to operate and control the movement of cranes, such as the boom and trolley. They come in various designs, from simple push-button controls to advanced computerized systems. It is important to choose the right control system for the job to ensure safe and efficient crane operations.

8. Cables: Cables are used to transmit power and signals in cranes, such as for operating the motor and control systems. They come in various sizes and designs to accommodate different crane models and applications. It is important to regularly inspect cables for wear and tear and replace them when necessary.

9. Counterweights: Counterweights are used to balance the load in cranes and prevent tipping or overloading. They come in various sizes and weights to accommodate different crane models and load capacities. It is important to choose the right counterweight for the job to ensure safe lifting operations.

| Serial Number | Product Name |

| 1 | LDP electric single beam |

| 2 | Semi – gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

10. Safety devices: Safety devices are essential in cranes to prevent accidents and injuries. They include devices such as limit switches, overload sensors, and emergency stop buttons. It is important to regularly inspect and test safety devices to ensure they are functioning properly.

In conclusion, having the right crane parts is essential for efficient and safe crane operations. By investing in quality crane parts and regularly inspecting and maintaining them, you can ensure that your cranes operate smoothly and efficiently. Remember to choose the right parts for the job and follow proper safety procedures to prevent accidents and injuries.

How to Properly Maintain Crane Parts to Extend Lifespan

Cranes are essential pieces of equipment in various industries, from construction to manufacturing. They are used to lift and move heavy loads, making them indispensable in many operations. However, like any machinery, cranes require regular maintenance to ensure they function properly and safely. One crucial aspect of crane maintenance is taking care of its parts to extend their lifespan and prevent costly breakdowns.

Proper maintenance of crane parts starts with regular inspections. Inspecting the crane parts for signs of wear and tear can help identify potential issues before they escalate into major problems. Look for any cracks, corrosion, or loose bolts that could compromise the crane’s performance. Pay special attention to high-stress components such as the hoist, wire ropes, and hooks, as they are more prone to wear and tear.

In addition to visual inspections, it is essential to follow the manufacturer’s recommended maintenance schedule. This includes lubricating moving parts, checking fluid levels, and replacing worn-out components. Regular maintenance not only extends the lifespan of crane parts but also ensures the crane operates efficiently and safely.

When it comes to maintaining crane parts, cleanliness is key. Dirt, dust, and debris can accumulate on crane parts, leading to premature wear and corrosion. Regularly clean the crane parts using a mild detergent and water to remove any buildup. Pay attention to hard-to-reach areas such as the sheaves, pins, and bearings, as they are more susceptible to dirt accumulation.

Another crucial aspect of crane maintenance is proper storage. When not in use, crane parts should be stored in a clean, dry, and well-ventilated area to prevent rust and corrosion. Avoid storing crane parts near chemicals, moisture, or extreme temperatures, as they can damage the components. Use protective covers or cases to shield the parts from dust and debris.

Properly maintaining crane parts also involves training your staff on how to handle and operate the equipment safely. Ensure that your operators are well-trained and certified to operate cranes, as improper use can lead to accidents and damage to crane parts. Provide regular training sessions on crane safety, maintenance procedures, and emergency protocols to keep your staff informed and prepared.

Investing in quality crane parts is another way to extend their lifespan. While it may be tempting to opt for cheaper alternatives, low-quality parts can compromise the crane’s performance and safety. Choose reputable manufacturers that offer durable and reliable crane parts to ensure the longevity of your equipment.

In conclusion, proper maintenance of crane parts is essential to extend their lifespan and ensure the safe and efficient operation of cranes. Regular inspections, following the manufacturer’s maintenance schedule, keeping the parts clean, proper storage, training your staff, and investing in quality parts are all crucial aspects of crane maintenance. By taking care of your crane parts, you can prevent costly breakdowns, improve productivity, and ensure the safety of your operations.

The Impact of Advanced Technology on Crane Parts Manufacturing in Factories

The manufacturing industry has seen significant advancements in technology over the years, and this has had a profound impact on the production of crane parts in factories. With the introduction of advanced technology, factories are now able to produce crane parts more efficiently and with higher precision than ever before. This has not only improved the quality of crane parts but has also increased the overall productivity of factories.

One of the key advancements in technology that has revolutionized crane parts manufacturing is the use of computer-aided design (CAD) software. CAD software allows engineers to design crane parts with incredible precision and detail, ensuring that each part is manufactured to exact specifications. This has greatly reduced the margin of error in production, resulting in higher quality crane parts that are less likely to fail.

In addition to CAD software, factories are also utilizing computer numerical control (CNC) machines to manufacture crane parts. CNC machines are able to produce parts with a level of accuracy that is simply not possible with traditional machining methods. This has allowed factories to produce crane parts with complex geometries and tight tolerances, further improving the quality of the parts.

Furthermore, the use of robotics in crane parts manufacturing has also had a significant impact on the industry. Robots are able to perform repetitive tasks with incredible speed and precision, allowing factories to increase their production output while reducing labor costs. This has made crane parts manufacturing more efficient and cost-effective, ultimately benefiting both manufacturers and consumers.

Another important advancement in technology that has impacted crane parts manufacturing is the use of additive manufacturing, also known as 3D printing. 3D printing allows factories to produce crane parts layer by layer, resulting in parts that are lighter, stronger, and more durable than traditionally manufactured parts. This has opened up new possibilities for design and innovation in crane parts manufacturing, allowing engineers to create parts that were previously thought to be impossible to manufacture.

Overall, the impact of advanced technology on crane parts manufacturing in factories has been overwhelmingly positive. The use of CAD software, CNC machines, robotics, and 3D printing has improved the quality of crane parts, increased productivity, and reduced costs. As technology continues to advance, we can expect to see even more innovations in crane parts manufacturing, further improving the efficiency and quality of the industry.

In conclusion, the impact of advanced technology on crane parts manufacturing in factories cannot be overstated. The use of CAD software, CNC machines, robotics, and 3D printing has revolutionized the industry, allowing factories to produce crane parts with unprecedented precision and efficiency. As technology continues to evolve, we can expect to see even more advancements in crane parts manufacturing, further solidifying the industry’s position as a leader in manufacturing innovation.