Table of Contents

Advantages of Using 200 Tons Type A Hook Gantry Crane in Factories

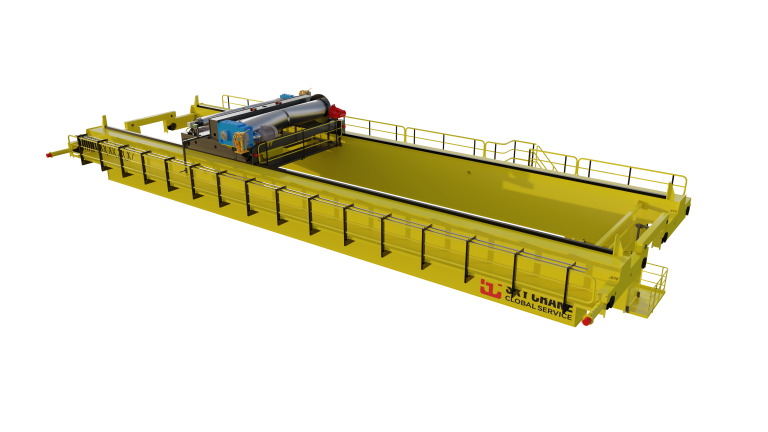

Gantry cranes are essential equipment in factories and industrial settings for lifting and moving heavy loads. One popular type of gantry crane is the 200 tons type A hook gantry crane. This crane is designed to handle heavy loads up to 200 tons with ease, making it a valuable asset for factories that deal with large and heavy materials on a regular basis.

| Number | Product Name |

| 1 | QD OVERHEAD CRANE WITH HOOK CAP.5-800/150T |

| 2 | Single – girder Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

One of the main advantages of using a 200 tons type A hook gantry crane in factories is its high lifting capacity. With a lifting capacity of up to 200 tons, this crane can easily handle heavy machinery, equipment, and materials, making it ideal for factories that deal with large and heavy loads on a daily basis. This high lifting capacity allows factories to increase their productivity and efficiency by moving heavy loads quickly and safely.

Another advantage of the 200 tons type A hook gantry crane is its versatility. This crane can be used in a variety of applications, from loading and unloading materials to moving heavy machinery and equipment around the factory floor. Its ability to handle a wide range of tasks makes it a valuable asset for factories that need a versatile and reliable lifting solution.

In addition to its high lifting capacity and versatility, the 200 tons type A hook gantry crane is also known for its durability and reliability. This crane is built to withstand the rigors of daily use in a factory setting, with a sturdy construction and high-quality materials that ensure it can handle heavy loads safely and efficiently. Its reliability means that factories can depend on this crane to perform day in and day out without any issues, helping to minimize downtime and keep operations running smoothly.

Furthermore, the 200 tons type A hook gantry crane is designed for ease of use and operation. With intuitive controls and a user-friendly interface, this crane is easy for factory workers to operate, reducing the risk of accidents and injuries. Its smooth and precise movements make it easy to position heavy loads exactly where they need to be, improving efficiency and productivity in the factory.

Overall, the 200 tons type A hook gantry crane offers a range of advantages for factories looking to improve their lifting and moving capabilities. From its high lifting capacity and versatility to its durability, reliability, and ease of use, this crane is a valuable asset for any factory that deals with heavy loads on a regular basis. By investing in a 200 tons type A hook gantry crane, factories can increase their productivity, efficiency, and safety, helping to streamline operations and improve overall performance.

Safety Measures for Operating 200 Tons Type A Hook Gantry Crane in Factories

Operating a 200-ton type A hook gantry crane in factories requires strict adherence to safety measures to prevent accidents and ensure the well-being of workers. These cranes are powerful machines that can lift heavy loads, making them essential for various industrial applications. However, their size and capacity also pose significant risks if not operated correctly. In this article, we will discuss some essential safety measures that should be followed when operating a 200-ton type A hook gantry crane in factories.

First and foremost, it is crucial to ensure that only trained and certified operators are allowed to operate the crane. Operating such a large and powerful machine requires specialized skills and knowledge. Operators must undergo thorough training to understand the crane’s controls, capabilities, and safety procedures. Additionally, operators should be regularly evaluated to ensure they are competent and capable of safely operating the crane.

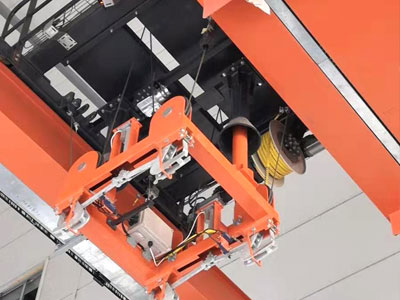

Before operating the crane, it is essential to conduct a pre-operational inspection to check for any signs of damage or wear. This includes inspecting the crane’s structure, controls, brakes, and hoisting mechanisms. Any issues should be addressed immediately to prevent accidents during operation. Regular maintenance and inspections are crucial to ensure the crane is in optimal working condition and safe to use.

When operating the crane, it is essential to follow all safety procedures and guidelines. This includes wearing appropriate personal protective equipment, such as hard hats, gloves, and safety glasses. Operators should also ensure that the area around the crane is clear of obstacles and personnel to prevent accidents. Communication is key when operating a crane, so operators should use hand signals or radios to communicate with ground personnel effectively.

When lifting heavy loads with the crane, it is crucial to ensure that the load is properly secured and balanced. Overloading the crane can cause it to tip over or collapse, leading to serious injuries or fatalities. Operators should always refer to the crane’s load chart to determine the maximum weight capacity and ensure that the load does not exceed this limit. Additionally, operators should be aware of the crane’s stability and avoid sudden movements or jerky motions that can destabilize the crane.

In the event of an emergency or malfunction, operators should know how to safely shut down the crane and evacuate the area. This includes knowing the location of emergency stop buttons and procedures for safely lowering the load in case of a power failure. Regular emergency drills and training can help operators prepare for unexpected situations and respond quickly and effectively.

In conclusion, operating a 200-ton type A hook gantry crane in factories requires strict adherence to safety measures to prevent accidents and ensure the well-being of workers. By following proper training, maintenance, and operational procedures, operators can safely and efficiently use these powerful machines to lift heavy loads and improve productivity in industrial settings. Safety should always be the top priority when operating a crane, and all personnel involved should be aware of the risks and precautions necessary to prevent accidents and injuries.

Maintenance Tips for Ensuring Longevity of 200 Tons Type A Hook Gantry Crane in Factories

A 200 tons type A hook gantry crane is a crucial piece of equipment in factories that handle heavy loads on a daily basis. To ensure the longevity and optimal performance of this crane, proper maintenance is essential. Neglecting maintenance can lead to breakdowns, costly repairs, and even safety hazards in the workplace. In this article, we will discuss some key maintenance tips for ensuring the longevity of a 200 tons type A hook gantry crane in factories.

Regular inspections are the first step in maintaining a 200 tons type A hook gantry crane. Inspections should be conducted by trained professionals who are familiar with the crane’s components and operation. During inspections, all parts of the crane should be thoroughly examined for signs of wear and tear, damage, or corrosion. Any issues should be addressed promptly to prevent further damage and ensure the crane’s safe operation.

In addition to regular inspections, lubrication is another important aspect of crane maintenance. Proper lubrication helps reduce friction between moving parts, which can prevent premature wear and extend the crane’s lifespan. The manufacturer’s guidelines should be followed when selecting the appropriate lubricants and applying them to the crane’s components. Over-lubrication should be avoided, as it can attract dust and debris, leading to potential damage.

Another crucial maintenance tip for ensuring the longevity of a 200 tons type A hook gantry crane is to keep the crane clean. Dust, dirt, and debris can accumulate on the crane’s components, causing them to wear out faster. Regular cleaning with a mild detergent and water can help prevent this buildup and keep the crane in optimal condition. Additionally, cleaning the crane can help identify any potential issues that may need to be addressed during inspections.

Proper storage of the crane when not in use is also important for maintaining its longevity. The crane should be stored in a dry, well-ventilated area to prevent rust and corrosion. Components that are not in use should be properly secured to prevent damage. Additionally, the crane should be protected from extreme temperatures, as this can affect its performance and lifespan.

Regular testing of the crane’s safety features is another essential maintenance tip. Safety features such as limit switches, emergency stop buttons, and overload protection systems should be tested regularly to ensure they are functioning properly. Any issues should be addressed immediately to prevent accidents and injuries in the workplace.

Lastly, training employees on the proper operation and maintenance of the 200 tons type A hook gantry crane is crucial for ensuring its longevity. Employees should be familiar with the crane’s operation manual and safety guidelines. They should also be trained on how to conduct basic maintenance tasks and identify potential issues that may require professional attention.

In conclusion, proper maintenance is essential for ensuring the longevity of a 200 tons type A hook gantry crane in factories. Regular inspections, lubrication, cleaning, proper storage, testing of safety features, and employee training are all key aspects of crane maintenance. By following these maintenance tips, factories can extend the lifespan of their cranes, reduce downtime, and ensure a safe working environment for their employees.